How is 3D printing carried out? As we saw earlier, the 3D printing process involves constructing an object by layering molten plastic. The object is built up as the next layer is printed on top and set as each layer sets. A digital file that instructs the 3D printer where to print the material is required for a 3D print. G-code files are the most common file format for this.

The X, Y, and Z axes, which serve to direct the printer’s horizontal and vertical movements, are basically contained in this file. These layers can be printed at various layer heights using a 3D printer. A print with more layers will have a higher “resolution,” somewhat analogous to pixels on a screen. Although it will take longer to print, this will produce a better-looking result.

What’s better, additive manufacturing or 3D printing? 3D printing is also known as “additive manufacturing” due to the addition of layers. The terms are frequently used to describe the same manufacturing process. Contrast “subtractive” processes like CNC machining, where material is removed (or subtracted) from a larger block to create the final object, with additive manufacturing.

3D printing with FDM versus FFF: an explanation Seeing references to the FDM (fused deposition modeling) and FFF (fused filament fabrication) processes is another thing that may cause newcomers to 3D printing to become confused about the process. Since they both refer to a particular kind of 3D printer, these are really just different names for the same thing. What kinds of 3D printers are there? Yes! But don’t worry about being confused; we’ll look at these briefly next.

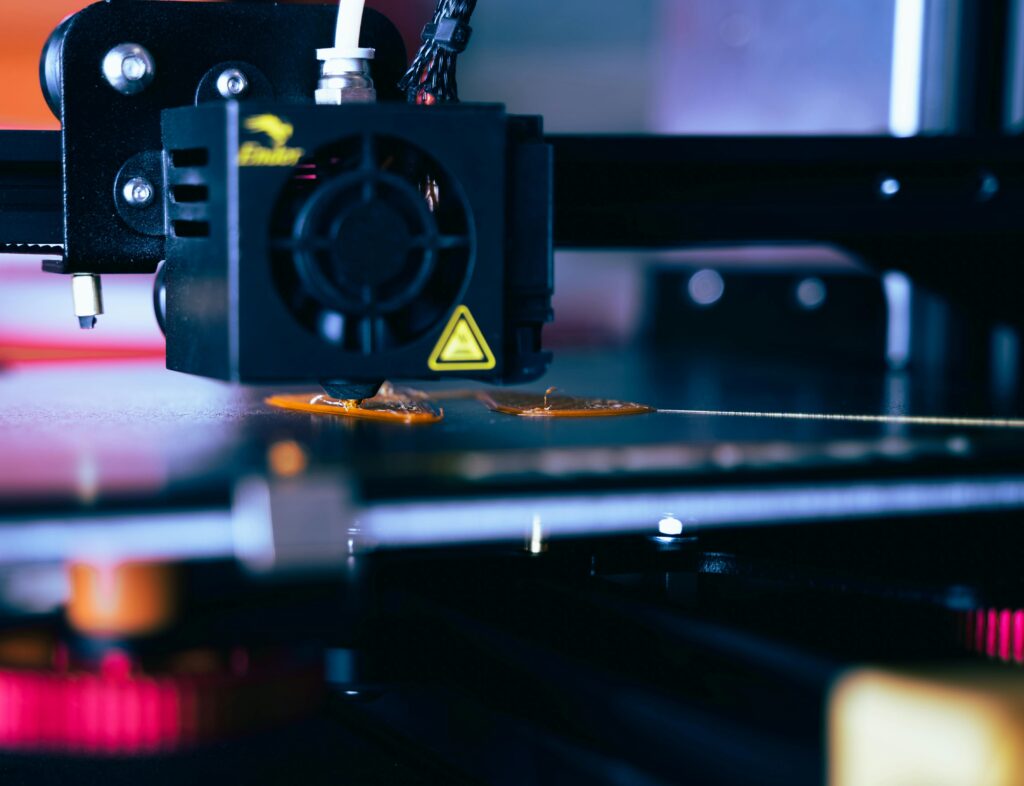

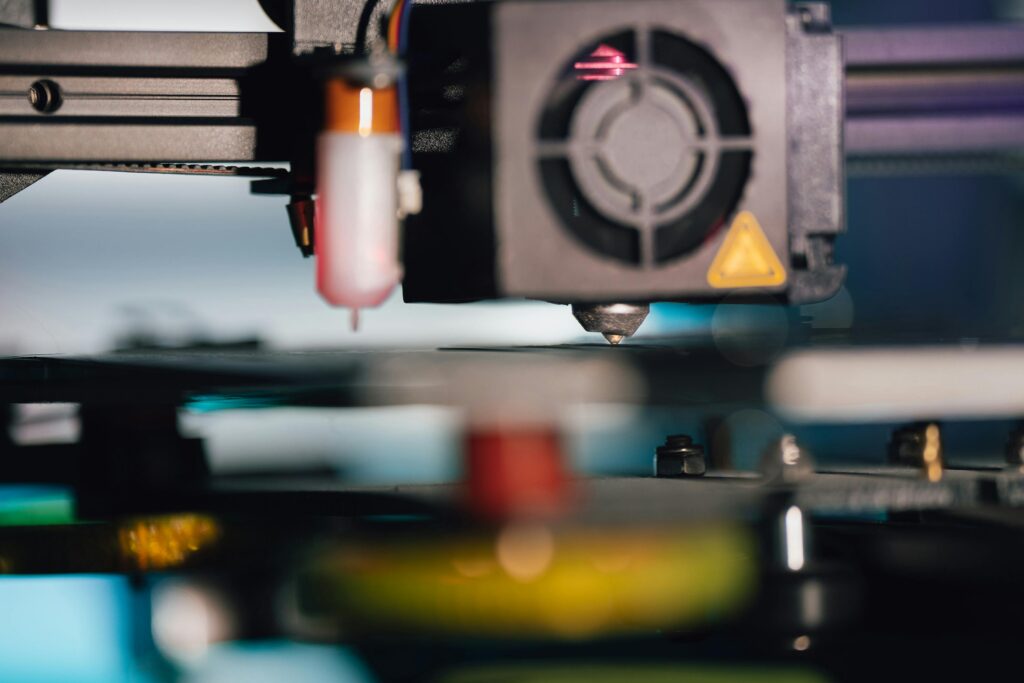

What are the various technologies used in 3D printing? Because of their adaptability, plastics can be used in a variety of manufacturing processes. Since 3D printing is not an exception, let’s investigate the various approaches. FFF 3D printing, SLA (stereolithography), and SLS (selective laser sintering) are the technologies that are utilized the most frequently. How does FFF 3D printing work? Through a heated nozzle, an FFF printer extrudes a thick string of material known as filament.

A motion system moves the nozzle around a build area so that melted filament can be deposited on a build plate. The build plate moves down by a millimeter or two layer by layer until the object is finished as the material cools and solidifies.

What is 3D printing with SLA? The raw material for SLA 3D printing is a UV-curable resin. A build platform is poured into a glass-bottomed container containing the resin. UV light is directed at the resin by a laser, which selectively hardens the required cross-section. In order to construct the print, the platform gradually rises out of the container.

What is 3D printing with SLS? A powdered raw material, typically a polymer, is used in SLS 3D printing. A blade spreads a thin layer of the powder onto the build area as it sits in a container. A laser fuses the small material particles together to form a single horizontal layer of the part. After that, the container moves a millimeter or two to start a new layer, and the blade swipes across the build area to deposit a new layer of raw material.

The finished product is made by repeating this process. What kinds of substances are used in 3D printing? The most prevalent material utilized in 3D printing is plastic polymers. It is possible to use different materials. Metal 3D printers, for instance, exist, but they are more niche than polymer printers. Additionally, construction materials like concrete are beginning to be processed by supersized machines based on 3D printing technology.

Polymer and other material blends can be printed with mainstream 3D printer types like FFF and SLS. Some of the properties of the blended material are offered by these, which are referred to as composites. The terms “3D printing material” and “3D printing filament” may be used interchangeably when discussing FFF 3D printing. This is due to the fact that the raw materials come on thin filament spools. We’ll go over a few different types of 3D printing filaments in greater depth in the following sections. Materials for beginning 3D printing PLA

PLA is the preferred beginner’s filament because it is derived from organic, renewable resources and easy to print with. PLA has excellent visual properties as well. However, PLA is frequently overlooked for mechanical and functional applications due to its low temperature resistance and deteriorating mechanical properties. PETG

PETG has emerged as one of the most widely used materials for 3D printing thanks to its well-balanced combination of properties. It is easy to classify it as “engineering material,” but due to its good printability, it is also a good option for beginners. It’s the go-to filament for engineering applications for many users because it has good thermal properties, is resistant to impact and chemicals, and is less expensive than many other engineering materials. constructing materials for 3D printing Nylon

Nylon is a versatile option for end-use parts because it can withstand significant mechanical stress and chemical resistance. ABS

ABS is a material for more demanding applications due to its superior mechanical and heat resistance to PLA. However, printing with it can be challenging, particularly on a less expensive open-frame 3D printer. A much more trustworthy experience is provided by a temperature-controlled and enclosed build chamber.