If you’ve ever worked with an FDM 3D printer, you probably know how slow it can be to print anything big or dense. Indeed, there are many limiting factors to obtaining quick prints without compromising.To achieve even close to the quality of a traditionally manufactured part, like an injection-molded , you normally have to print with slower speeds and other time-increasing settings to maintain detail. That’s because, at the most basic level, print quality and print speed are inversely correlated, meaning that when one goes up, the other goes down.

But this is only part of the story. There are many ways to reduce printing time without causing the results to suffer, but it can take some work to identify and tune the right settings to balance low print time and high print quality. This tuning process is repetitive and tedious, involving tweaking settings and printing tests until you achieve the print time you’re looking for without significant quality defects. Many settings affect speed, and in this article, we’ll go over what you can do to reduce printing time. We’ll first look at motion systems suitable for high speed printing. Then, we’ll dive into speed settings for the print head as well as other settings that need to be adjusted to balance faster speeds. Aft f you’ve ever worked with an FDM 3D printer, you probably know how slow it can be to print anything big or dense. Indeed, there are many limiting factors to obtaining quick prints without compromising on quality.

To achieve even close to the quality of a traditionally manufactured part, like an injection-molded Lego brick, you normally have to print with slower speeds and other time-increasing settings to maintain detail. That’s because, at the most basic level, print quality and print speed are inversely correlated, meaning that when one goes up, the other goes down.

But this is only part of the story. There are many ways to reduce printing time without causing the results to suffer, but it can take some work to identify and tune the right settings to balance low print time and high print quality. This tuning process is repetitive and tedious, involving tweaking settings and printing tests until you achieve the print time you’re looking for without significant quality defects.

Many settings affect speed, and in this article, we’ll go over what you can do to reduce printing time. We’ll first look at motion systems suitable for high speed printing. Then, we’ll dive into speed settings for the print head as well as other settings that need to be adjusted to balance faster speeds. After that, we’ll review other important print settings that can help reduce printing time, using Cura as the example slicer. Enjoy!

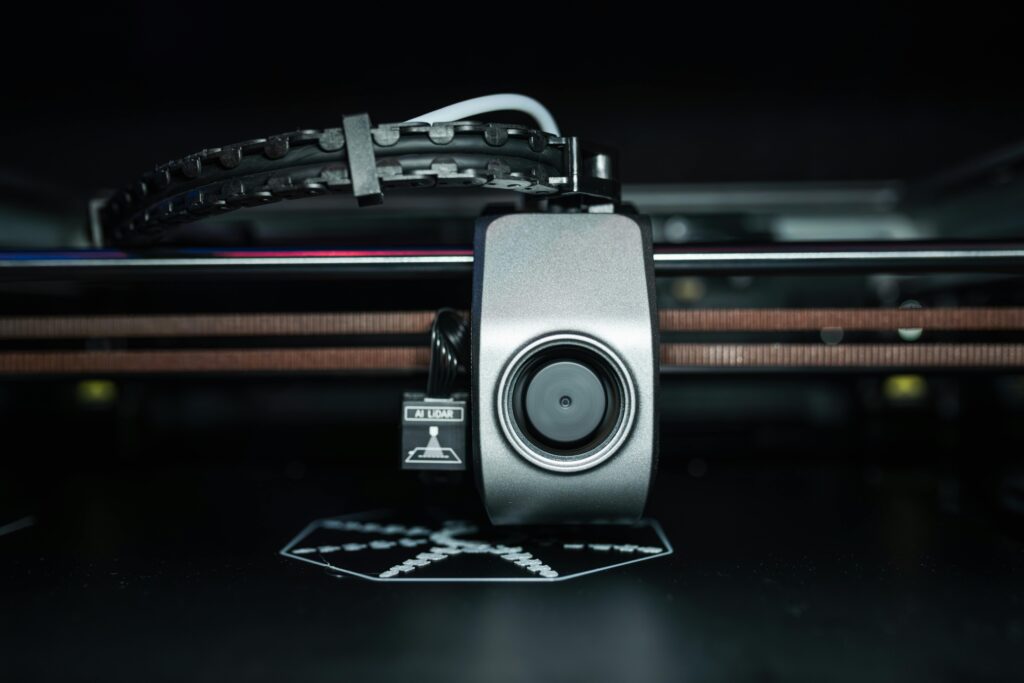

Not all 3D printers are built the same, and we aren’t just talking about the components, but rather the motion system they use in their design. Some 3D printers are faster than others simply because they use a motion system that allows for faster movements, such as delta or CoreXY printers.

Delta printers are usually quite tall and have a fixed bed with a print head that’s moved by three vertically mounted stepper motors. On the other hand, CoreXY printers have a print head that moves along the X- and Y-axes while the bed moves up and down. Both of these motion systems benefit from not having to move the bed on the Y-axis, unlike bed slingers. This slows things down, as print beds are usually heavy.

The motion system, together with the quality of the components, will ultimately determine the printing speed possible for your printer. It’s important to know what type of printer you’re working with and look at speed values from fellow makers using stock or modded printers.

Your print speed settings contain the different speed values for your printer when it’s doing specific actions (infill, walls, top and bottom layers, and other printing actions). The first thing you should do is open up your slicer, head over to the speed settings section, and make sure all the adjustable settings are visible so you have a complete picture of your options.

For the print speeds that are set slower by default, you can start by increasing these to be equal to the other values. Exceptions include if the part you’re printing is meant for display, in which case you may want to set the “Wall” speed slightly lower than your other print speeds. At the same time, make sure to increase the “Skirt/Brim Speed” if you’re using one, as this speed is slower by default but won’t affect the quality of the final print.

For PLA and ABS, some typical speeds are 40-60 mm/s, but you might like to try even faster. When increasing print speed, do so in intervals of 5 mm/s, as too large a change can present many problems at once. It’s better to solve print quality issues one by one and in increments, rather than attack them all at once.er that, we’ll review other important print settings that can help reduce printing time, using Cura as the example slicer. Enjoy!

Not all 3D printers are built the same, and we aren’t just talking about the components, but rather the motion system they use in their design. Some 3D printers are faster than others simply because they use a motion system that allows for faster movements,

Delta printers are usually quite tall and have a fixed bed with a print head that’s moved by three vertically mounted stepper motors. On the other hand, have a print head that moves along the X- and Y-axes while the bed moves up and down. Both of these motion systems benefit from not having to move the bed on the Y-axis, unlike . This slows things down, as print beds are usually heavy.

The motion system, together with the quality of the components, will ultimately determine the printing speed possible for your printer. It’s important to know what type of printer you’re working with and look at speed values from fellow makers using stock or modded printers.

Your print speed settings contain the different speed values for your printer when it’s doing specific actions (infill, walls, top and bottom layers, and other printing actions). The first thing you should do is open up your slicer, head over to the speed settings section, and make sure all the adjustable settings are visible so you have a complete picture of your options.

For the print speeds that are set slower by default, you can start by increasing these to be equal to the other values. Exceptions include if the part you’re printing is meant for display, in which case you may want to set the “Wall” speed slightly lower than your other print speeds. At the same time, make sure to increase the “Skirt/Brim Speed” if you’re using one, as this speed is slower by default but won’t affect the quality of the final print.

For PLA and ABS, some typical speeds are 40-60 mm/s, but you might like to try even faster. When increasing print speed, do so in intervals of 5 mm/s, as too large a change can present many problems at once. It’s better to solve print quality issues one by one and in increments, rather than attack them all at once.