Physical architectural models continue to play a significant role in architects’ ability to visualize blueprints, despite the transition from the drawing board to digital screens. Technologies for 3D printing enable architects and model makers to quickly and economically create high-precision architectural models directly from digital drawings, bridging the digital and physical worlds.

The various architectural 3D printing processes, as well as the procedure for producing 3D printed models from architectural computer-aided design (CAD) software, are all covered in depth in this guide. Why are architectural models printed in 3D? Architectural models have been used as physical representations during the construction of buildings since the time of the Pharaohs to help sell projects, support fundraising efforts, and resolve construction issues.

Model-making is typically a labor-intensive and repetitive manual craft that involves working with materials like wood, ceramic, cardboard, or clay. Nowadays, architecture studios and practices have access to a wider variety of tools, such as CNC milling machines, laser cutters, and 3D printers, which can speed up the workflow and reduce labor requirements. Architects and model makers now have access to cutting-edge 3D printing techniques that can completely change the way models are made. This is done by:

• Easing the process of creating architectural models.

• Converting CAD drawings into tangible 3D models with extreme precision.

• Producing parts with intricate designs that would be difficult or impossible to manufacture by hand.

•Make communication easier and highlight specific areas that would be difficult to convey through standard two-dimensional drawings.

• Increasing the number of design iterations while lowering production costs.

Model makers like Renzo Piano Building Workshop (RPBW), which was started by the architect who won the Pritzker Prize, use an SLA 3D printer to quickly make accurate models. Our models are updated on a daily or even hourly basis. We don’t have enough time to manually complete the project because the architects change it quickly. As a result, we need to find a faster method,” Francesco Terranova, RPBW model maker, stated. Models can be made with 3D printers in a few hours or even overnight to save time. The good news is that we can start the printer at night and find the model finished when we get up in the morning. We don’t lose any time during the day this way, “Mr. Terranova.

The trees in this model were 3D printed on a Formlabs SLA 3D printer, which is ideal for intricate parts in architecture. In addition to being used in conjunction with other tools and procedures, 3D printing can be used to create architectural models of entire buildings.

The base parts of RPBW’s architectural models can be made with CNC machining or laser cutting, and more complicated or intricate parts like stairs, trees, spheres, and curved surfaces, which would take a long time to make by hand, can be made with a 3D printer. The RPBW team, for instance, 3D printed the intricate columns’ joints for the Genoa-based model of the new San-Giorgio motorway bridge, which has replaced the Morandi bridge, which collapsed in 2018. The creative process is sped up and the accuracy of architectural models is improved when traditional manufacturing methods are combined with 3D printing. One of the main goals of 3D architecture models is to make it easier for architects to communicate with one another and for clients to see plans.

Communication of a building’s or home’s scale is especially important for Laney LA, a Los Angeles-based design firm that mostly works on custom homes. Using 3D printing, architect Paul Choi and his team can show specific parts of the project that are hard to show with traditional 2D drawings. The architects at Laney LA use 3D printing to create models that provide vantage points and enable them to see the project from a new angle. Choi stated, “It’s fun to always try to depict a certain idea about the project and isolate that through the model.” This could be a particular room or space we want to highlight through a section cut of the model, or even the topography of the site.

The model makers at RPBW make use of a Form 3 SLA printer to produce scale models more quickly. How to Choose a 3D Printer for Building Models There are a variety of approaches to 3D printing architectural models.

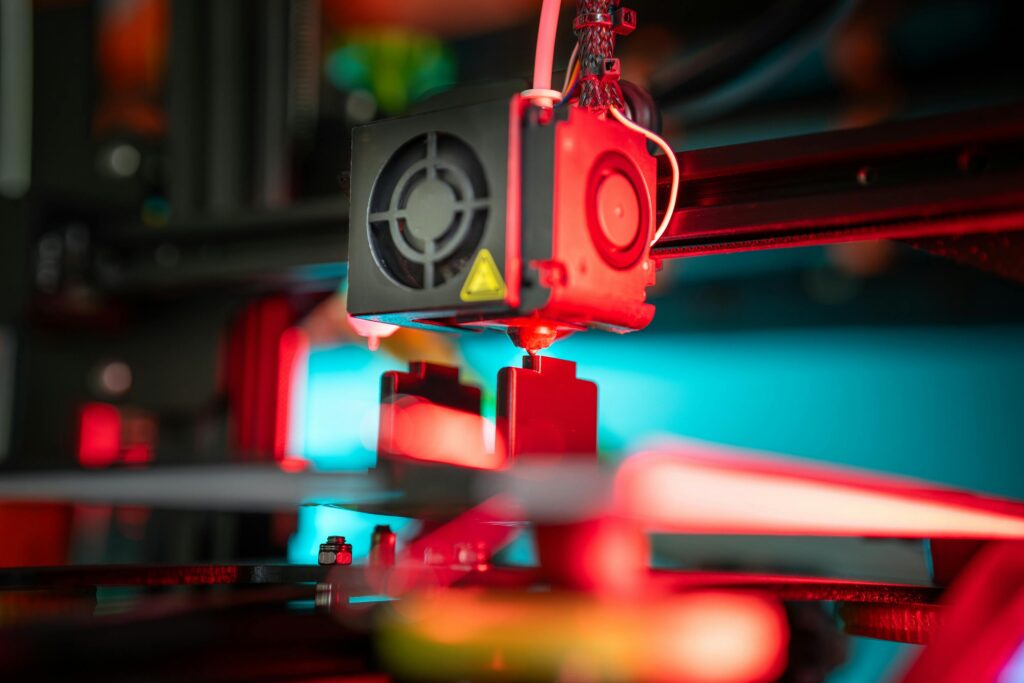

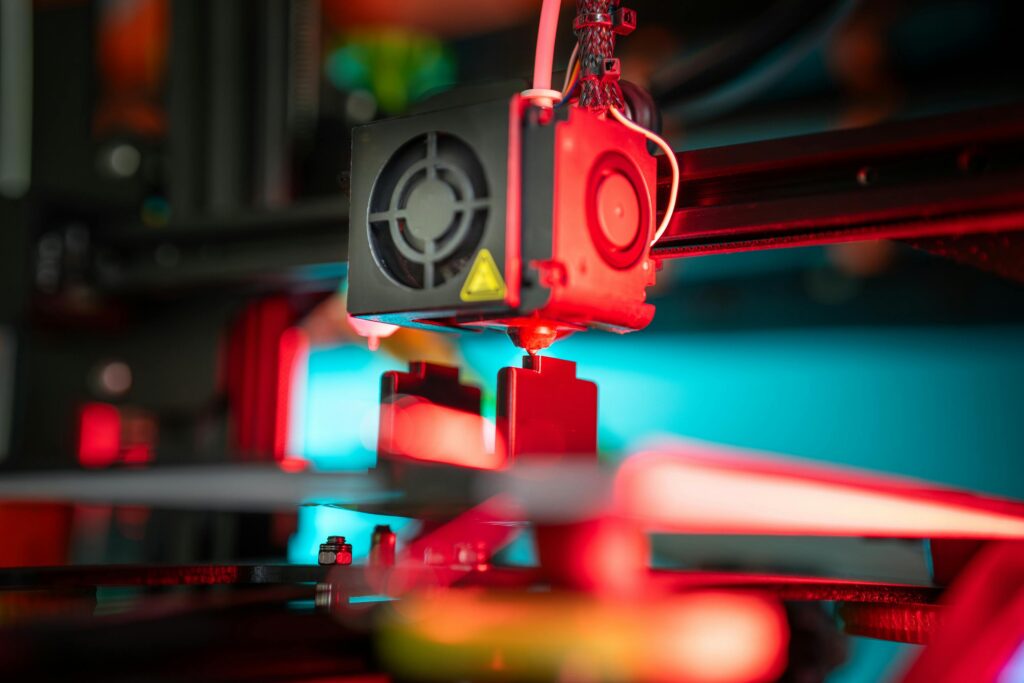

It is essential to select the appropriate printing technology for particular use cases. Stereolithography (SLA), fused deposition modeling (FDM), selective laser sintering (SLS), and binder jetting are the three most widely used 3D printing techniques for architectural models. SLA (stereolithography) In the 1980s, stereolithography was developed.

It is still one of the most widely used 3D printing technologies among professionals. In a process known as photopolymerization, SLA resin 3D printers use a laser to turn liquid resin into hardened plastic. Among all plastic 3D printing technologies, SLA parts have the highest resolution and accuracy.

Additionally, SLA components provide the smoothest and easiest-to-paint surface finish. SLA parts are ideal for highly detailed presentation models because they have sharp edges, a smooth surface finish, and few layer lines that are visible. A Form 3 SLA printer was used to print this model. For concepts and ideas that need to be presented to clients or the general public not the best choice for printing complex designs or parts with intricate features because it has the lowest resolution and accuracy of the four 3D printing processes.d industrial additive manufacturing technique is selective laser sintering. Small polymer powder particles are fused by SLS 3D printers using a powerful laser. During printing, the part is supported by the unfused powder, eliminating the need for special support structures.