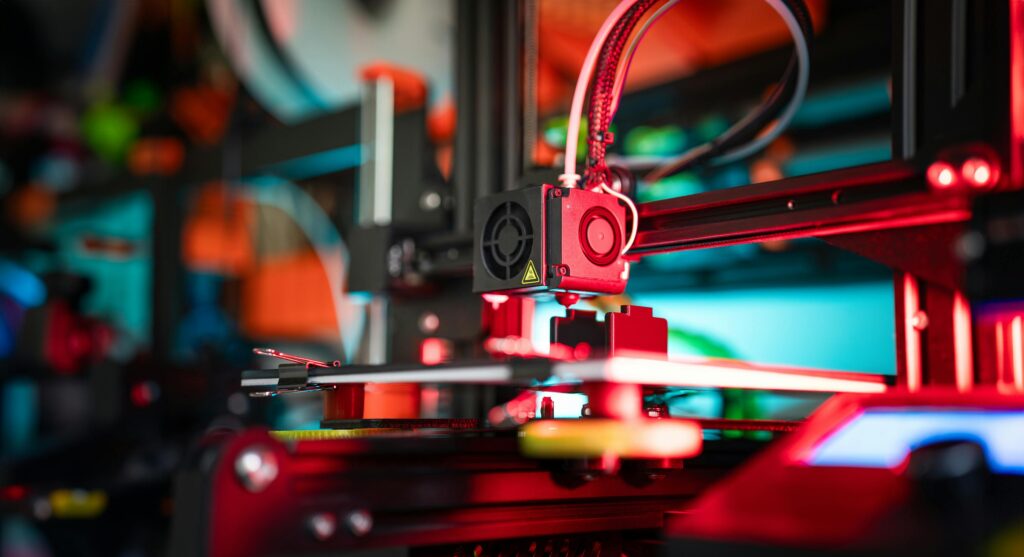

During an age where innovation is the heartbeat of progress, FDM 3D printing stands as a testament to human ingenuity. No longer confined to the realms of science fiction, this technology has gracefully waltzed into our reality, reshaping the contours of design, manufacturing, and artistic expression. Throughout this exploration of FDM 3D printing, prepare to peel back the layers of a technique that’s as intricate as it is transformative. From its foundational principles to its vast applications, let’s figure out what makes FDM 3D printing so amazing.

What is FDM 3D Printing? To start, let’s define the FDM 3D printing meaning. So, what is an FDM 3D printer? And what does FDM stand for in 3D printing? FDM, standing for Fused Deposition Modeling, is a revolutionary 3D printing technique that has transformed the way we create and prototype objects. If you’ve ever been curious about how those intricate 3D-printed models are made or wondered about the technology behind the magic, then you’re in the right place. Let’s dive deep into understanding what FDM 3D printing is all about. At its core, FDM 3D printing is all about transforming digital designs into tangible, three-dimensional objects. Imagine having a digital blueprint of a toy, a tool, or even a piece of jewelry, and then watching it come to life layer by layer, right before your eyes. That is how FDM 3D printing works. Characteristics of FDM 3D Printing

• Layer-by-Layer Construction: FDM builds objects layer by layer, in contrast to conventional manufacturing techniques that sculpt or carve objects out of blocks of material. This additive process allows for intricate designs and structures that would be impossible with subtractive methods.

• Thermoplastic Materials: FDM uses thermoplastic materials, which are heated to a molten state and then extruded through a nozzle. The layers of the 3D object are formed by the material as it cools and solidifies. • Support Structures: For designs with overhangs or bridges, FDM printers create temporary support structures that can be easily removed post-printing. The integrity and accuracy of the printed object are guaranteed by this.

• Variety of Colors and Materials: With FDM, you’re not limited to one color or material. Depending on the printer, you can use multiple colors and even combine different materials in a single print. Advantages and Disadvantages of FDM 3D Printing The advantages and disadvantages of FDM 3D printing are compared as follows: Advantages:

• Cost-Effective: Compared to other 3D printing methods, FDM is often more affordable, making it a popular choice for hobbyists and businesses alike.

• Versatility: With a wide range of materials available, FDM can be used for everything from prototypes to functional parts. • Ease of Use: Modern FDM 3d printers are user-friendly, with intuitive interfaces and software. Disadvantages : • Resolution Limits: While FDM is great for many applications, it might not be the best choice for objects that require ultra-fine details. • Material Constraints: Not all materials are suitable for FDM, which can limit its applications in certain industries. • Post-Processing: Some FDM prints might require additional finishing steps to achieve the desired surface finish or to remove support structures. How Does FDM Technology Work? Having learned what is FDM 3D printing, you might wonder about the mechanics behind this innovative process. Let’s break it down step by step:

1. Design Phase: Everything begins with a digital design. A special piece of software is used to create a 3D model. The model is then made into a digital file that the printer can read, usually in STL or OBJ format. 2. Using slicing software, the model is “sliced” into hundreds or even thousands of horizontal layers prior to printing. You can also adjust print settings like layer height, infill density, and print speed with this software. 3. Loading the Filament: The selected thermoplastic filament, which could range from PLA to ABS or even more specialized materials, is loaded into the printer. This filament acts as the “ink” for the 3D printer. 4. Heating: The printer’s nozzle and build plate are heated. The ideal temperature for various 3D printing filaments can be found here. The precise temperature is dependent on the type of filament. For instance, PLA might be extruded at around 200°C, while ABS requires a slightly higher temperature. 5. Printing: The heated nozzle starts extruding the melted filament onto the build plate, following the path set by the sliced model. It builds the object layer by layer, with each layer fusing to the one below it. 6. The extruded material begins to cool and solidify as it leaves the nozzle, resulting in a solid structure. 7. Support Structures: For models with overhanging parts, the printer creates support structures that can be removed post-printing.

8. Completion: Once all layers are printed, the object is left to cool down, and any support structures are carefully removed. You’ll have a better understanding of the intricacies of FDM 3D printing and the marvels it can produce if you understand this process. Common FDM 3D Printing Materials In the field of FDM 3D printing, you’ll quickly realize that there are varying types of FDM 3D printers and that the choice of material plays a pivotal role in the outcome of your print.

The most common kinds of filament for FDM printers are as follows: • PLA (Polylactic Acid): Derived from renewable resources like sugarcane, PLA is biodegradable and is known for its ease of use. It’s ideal for beginners and is commonly used for decorative items and prototypes. • ABS (Acrylonitrile Butadiene Styrene): A petroleum-based plastic, ABS is durable and can withstand higher temperatures than PLA. It is widely used for functional parts in electronics and automotive industries. • PETG (Polyethylene Terephthalate Glycol): Combining the best of both PLA and ABS, PETG offers durability and flexibility. Additionally, it resists moisture and UV light, making it suitable for use outdoors.

• TPU (Thermoplastic Polyurethane): If you’re looking for flexibility, TPU is the way to go. It is flexible and can be applied to footwear, medical devices, and phone cases. • Nylon: Known for its strength and durability, Nylon is resistant to wear and tear. It is used for functional parts in aerospace and automotive industries. • PEEK (Polyether Ether Ketone): PEEK is a high-performance material that is resistant to chemicals and can withstand high temperatures. It’s used in demanding applications in the medical and aerospace sectors. When choosing a material, consider the purpose of your print. Do you need flexibility, strength, or heat resistance? By understanding the properties of each material and feature, you can make an informed decision and ensure the success of your 3D printing project.

Which FDM 3D Printer Is Best? Exploring the possibilities with 3D printing can be exhilarating, but with so many options available, how do you pinpoint the best FDM 3D printer for your needs? A step-by-step guide to help you consider this option is provided below:

1. Determine Your Purpose: Before diving into the specifics, ask yourself – what’s the primary purpose of your 3D printer? Are you a hobbyist looking to create fun projects, or a professional needing high-quality prototypes? Your choice will be guided by your response. 2. Build Volume: Consider the size of the objects you plan to print. If you’re aiming for larger models, you’ll need a printer with a FDM Applications for 3D Printing The versat