Discover how 3D printing is reshaping the jewellery industry with precision, customization, and faster production. Learn about its applications in creating intricate and innovative designs.

The 3D printing technology is capable of working with precious metals, the core components of jewellery. It creates joints which are stronger as jewellery is often created from one continuous piece of metal, rather than several pieces which have been welded together. This results in designs which are more accurate and intricate than those that have been created by hand, and, as mentioned, these designs can be a whole new range of 3D products that have previously been impossible to create.

One of the benefits of using this type of process in the jewellery industry is the level of efficiency that it brings. It’s not just for the whole printing of jewellery pieces that additive manufacturing is used. In some cases, 3D print moulds of the models are created from wax or resin. The moulds will be placed into a cast, and then the molten metal will be poured in. This dissolves the wax and leaves behind the solid metal jewellery. 3D Printing for Jewelry: Achieve intricate designs, faster production

Current Industry Scenario

3D printing is trending recently with cutting edge jewellery producers, as it can produce designs on demand and is able to market new products quickly. With the need to move forward with contemporary demands in customized jewellery of millennial consumers, companies are being pushed forward to embrace the advancement in manufacturing technologies. 3D printing, apart from being an incredibly efficient way to produce jewellery, is also an enabler of delicate and original designs. It transforms traditional production model to digital and rapid jewelry solution.

Digital technologies are not only making jewellery easier to customize, but also simpler to mass-produce designs. Stereolithography, 3D printing technology can reproduce complex features which are difficult to hand-carve in no time.

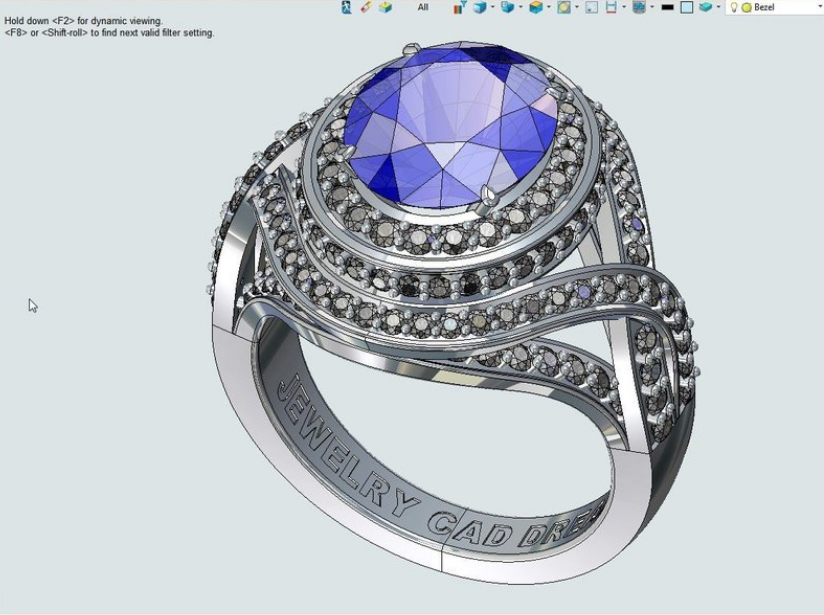

As the scope for 3D printing in jewellery industry seems almost limitless to create simpler, yet elegant, products. Designers in particular have taken a high degree of interest in using 3D printing to make their thoughts come to life. Using CAD software, in many ways one is only restricted by their own thoughts. 3D printing allows for new varieties of jewellery to be created with ease.

In a world where consumers are after instant products and where industries need to be more efficient, 3D printing is the perfect solution for creating a whole range of intricate products.

Unleash the beauty of infinite possibilities with 3D printing in jewellery design.

3D printing in the jewellery industry is revolutionizing the way jewellery is designed and produced. By using 3D printing technology, jewellery designers and manufacturers can create complex and intricate designs with ease, bringing their creative visions to life. 3D printing also allows for greater customization and personalization of jewellery pieces. Additionally, it can reduce production costs and lead time, allowing for more efficient and cost-effective production. This technology also enables more sustainable practices by reducing waste and the need for certain types of mining. Overall, 3D printing in the jewellery industry is opening up new possibilities for design and production, making it an exciting and innovative field to be a part of.

5 Best Advantages Of Using 3D Printing In Jewellery Industry

Jewelry 3D printing has numerous advantages over traditional jewelry manufacturing techniques. One of the main benefits is the ability to create highly detailed and complex designs that would be difficult or impossible to produce using traditional methods. This allows for a greater level of creativity and artistic expression in the design process. Additionally, jewelry 3D printing is much faster and more efficient than traditional methods, resulting in lower costs and faster production times. Another advantage is the ability to easily make small changes or adjustments to designs without having to start from scratch. This can save both time and money in the design process. Additionally, jewelry 3D printing allows for a greater level of customization, as each piece can be tailored to the specific needs and preferences of the customer. Overall, jewelry 3D printing is a revolutionary technology that offers many benefits to both designers and customers.

1. Complex and intricate designs can be easily created with 3D printing technology

Steps to create a jewelry using 3D printing technology

Step 1: Designing the Jewelry

The first step in creating jewelry using 3D printing technology is to design the piece using computer-aided design (CAD) software. This allows for the creation of highly detailed and precise designs that would be difficult or impossible to produce using traditional methods. Many jewelry designers use software such as Rhino, ZBrush, or Autodesk Fusion 360 to create their designs. These programs provide a wide range of tools and features that allow designers to create detailed and complex designs. Additionally, many of these programs have built-in tutorials and guides that can help designers learn how to use the software and create their designs.

Step 2: Preparing the Model

Once the design is complete, the model needs to be prepared for printing. This includes checking for any errors or inconsistencies in the design and making any necessary adjustments. For example, designers may need to adjust the thickness of certain parts of the design or add additional supports to ensure that the piece will print properly. Additionally, designers may need to scale the design to the appropriate size and add any additional details or embellishments.

Step 3: Printing the Jewelry

The next step is to print the jewelry using a 3D printer. This can be done using a variety of materials, such as metals, plastics, or even ceramics. The most common materials used for jewelry 3D printing are metals such as gold, silver, and titanium. However, other materials such as plastic, ceramics, and even resin can also be used. The type of material used will depend on the final design and the desired properties of the finished piece.

Step 4: Finishing and polishing

After printing, the jewelry will need to be cleaned and finished. This may include polishing the surface, removing any excess material, and adding any additional details or embellishments. Depending on the material used, the finishing process may involve sanding, polishing, or even electroplating. The goal is to achieve a smooth and polished surface that is free of any defects or blemishes.