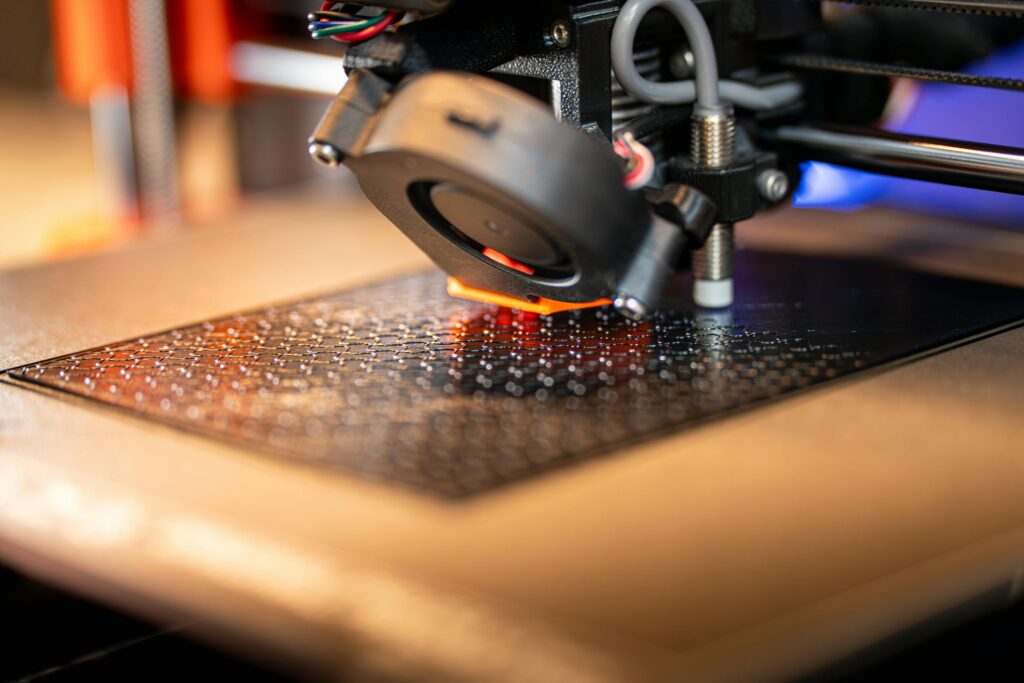

Since 3D printing is a very useful manufacturing technique, many people wonder if it is possible to successfully print automobiles or automobile parts. This article will answer some of your questions about 3D printing car parts and walk you through some techniques used by experts. Let’s take a general look at the question of whether you can 3D print car parts at home and a car as a whole before discussing how to 3D print car parts. Can Auto Parts Be 3D-Printed at Home? What automobile components can be 3D printed? It is possible to 3D print parts for cars from the comfort of your own home. While you won’t be able to 3D print the entire vehicle, you can print individual parts that can be assembled or joined to other parts of the vehicle.

A user mentioned printing BMW-specific replacement bodywork brackets. Additionally, they mentioned that they have friends who print individualized accessories and door knobs. Due to the complex curves that can be achieved, many Formula One car parts are now 3D printed because they are expensive if purchased from auto shops or online.

Using metal casting or metal additive manufacturing, it is also possible to 3D print car engine parts that work. This is how many engine parts are made, especially if they are for an old design that is no longer in production. Most of the parts are usually accessories, but larger 3D printers can 3D print actual car parts. Replica car models like the Tesla Model 3 and RC vehicles like The Batmobile (1989) and the 1991 Mazda 787B can also be printed in 3D. A YouTube prints a first-ever RC car using 3D printing in this video. You can look at other car models by searching on 3D printer file websites like Thing verse or Cults because the list of parts for 3D printing cars is endless. The procedure for 3D printing a brake line clip is demonstrated in the video below, further demonstrating the capability of 3D printing automotive components. The majority of well-known car brands 3D print some of their car parts and accessories. When it comes to car parts that can be 3D printed, BMW is probably the first brand that comes to mind.

In 2018, they announced that they had produced more than a million unique 3D-printed automobile parts. A window guide rail for the BMW i8 Roadster is their one millionth 3D printed automobile component. The company’s experts worked on the entire part for about five days before integrating it into series production shortly thereafter. BMW can now produce 100 window guide rails in a single day. The following other automakers produce their parts using 3D printing: • The Rolls-Royce The Porsche • Ford

• Volvo

• Bentley • Audi

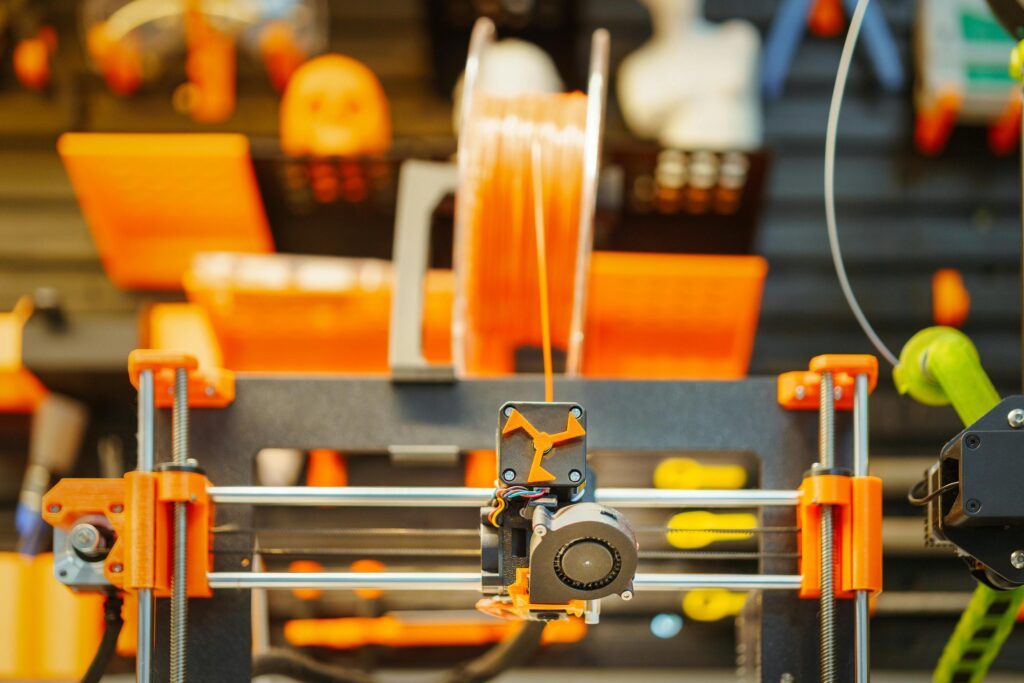

This demonstrates that it is possible to 3D print car parts for automobile manufacturers like these. Jordan Payne, a YouTuber, was able to use their Creality Ender 3 with ABS filament for increased heat resistance to create a new logo for their Datsun 280z. He mentioned that because of its high-quality software, he used a program called Fusion 360. To learn more about how he was able to 3D print the automobile’s logo, you can watch the entire video below. Can a car be printed in 3D? While it is not possible to 3D print every component of a vehicle, you can 3D print a significant portion of it, including the vehicle’s chassis, body, and internal structure. There may be some metal 3D-printed parts in other parts, like the engine, battery, and gears, but not every part can be 3D-printed. The Strati car, the world’s first 3D-printed vehicle, is one of the most impressive examples of a 3D-printed vehicle.

It was 3D printed in a single piece and took 44 hours to print, reducing the number of parts and increasing the likelihood of printing success. The Strati car is actually being tested in this video. A father who was awarded a brand-new Lamborghini Aventador 3D printed a replica of the car with his son. They were able to print the car replica after completing the project, which took almost a year and a half. Additionally, the father purchased a $900 3D printer and found an online car model diagram. They joined their individual, long-lasting plastic panels by soldering them together. Also, they used Nylon with Carbon Fiber filament to make the car’s interiors.

However, when they realized that they might not be able to 3D print movable parts like wheels and small electrical components, they went online and bought them. They were able to replicate the Lamborghini Aventador vehicle after a lot of trial and error. Because they are made of so many different materials, 3D printers are good at printing shapes but not so good at printing complex parts or components. Because of this, not every component of the most well-known 3D printed automobile is 3D printed. You can see how the Aventador came out by watching the video. On the other hand, you can use a hybrid technology like a 3D printer and a half robot to 3D print a half-size car model. According to José Antonio, the project’s coordinator, the model can be used to demonstrate a car’s style and design. The system combines 3D printing with a robot that allows materials to be curved because