How 3D Printing Functions

3D printing, otherwise called added substance producing, makes objects layer by layer from a computerized plan record. Here is a bit-by-bit breakdown of how it functions:

________________________________________

1. Planning the 3D Model

• A 3D model is made utilizing computer-aided design (PC Helped Plan) programming like Combination 360, Blender, or Tinkercad.

• The model is saved in a configuration like STL, OBJ, or 3MF.

________________________________________

• A slicer program (e.g., Cura, PrusaSlicer) changes the 3D model into slightly even layers.

• It produces G-code, which contains directions for the 3D printer (like development, temperature, and speed).

________________________________________

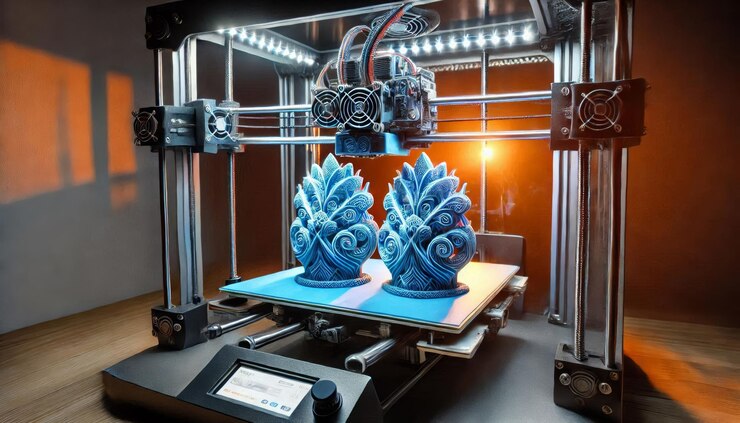

3. Printing Cycle (Layer-by-Layer)

Contingent upon the kind of 3D printing innovation utilized:

FDM (Intertwined Affidavit Demonstrating)

• The printer warms and expels plastic fiber (like PLA or ABS).

• The material is stored layer by layer onto the form plate.

• The layers meld as they cool, framing the last item.

SLA (Stereolithography)/DLP (Advanced Light Handling)

• A fluid sap is presented to UV light or a laser, which solidifies each layer.

• The form stage goes up, and the following layer is restored until the item is finished.

SLS (Specific Laser Sintering)/SLM (Particular Laser Dissolving)

• A laser sinters (wires) powdered materials (like nylon or metal).

• The interaction proceeds layer by layer until the part is framed.

________________________________________

• FDM prints might need help with expulsion, sanding, or painting.

• SLA/DLP prints need washing in isopropyl liquor and UV restoring to solidify completely.

• SLS/SLM prints could require expulsion of overabundant powder and surface wrapping up.