Have you at any point considered how 3D printing fiber is made, changing unrefined substances into the adaptable strands that power your innovative activities?

This creative cycle is at the core of the expanding 3D printing industry, which, as indicated by a report by Fabulous View Exploration, is supposed to develop at a build yearly development pace of 23.3% from 2023 to 2030.

As somebody who has watched the development of 3D printing from a specialty side interest to a standard innovation, I can see that the creation of fiber is both a craftsmanship and a science.

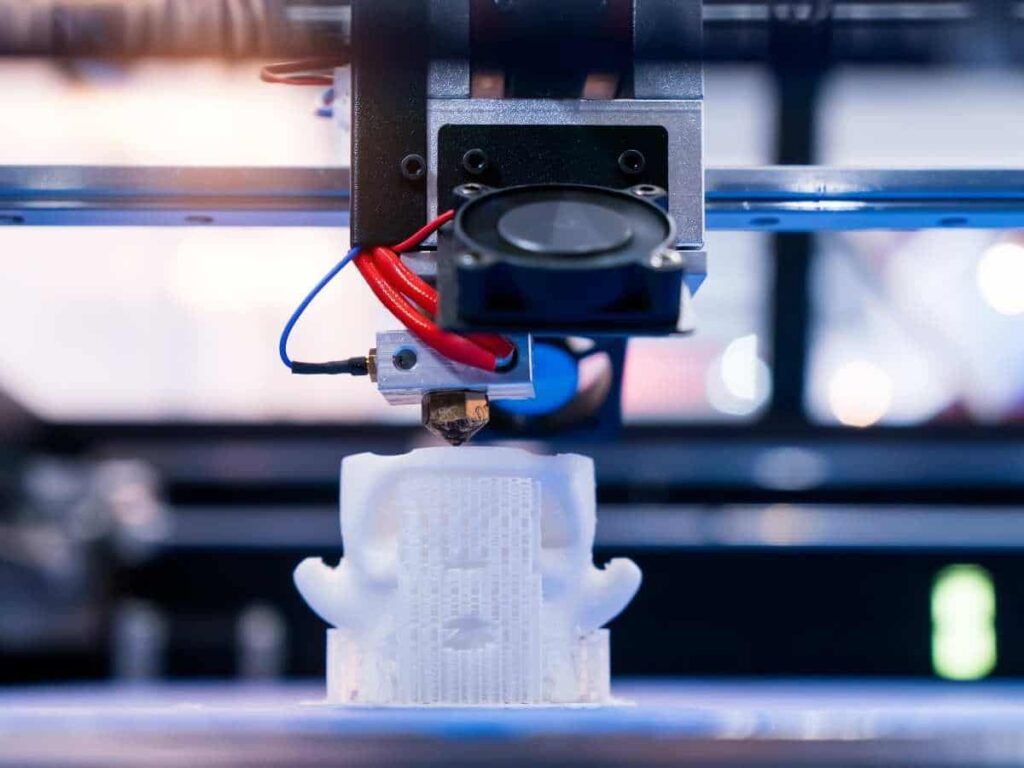

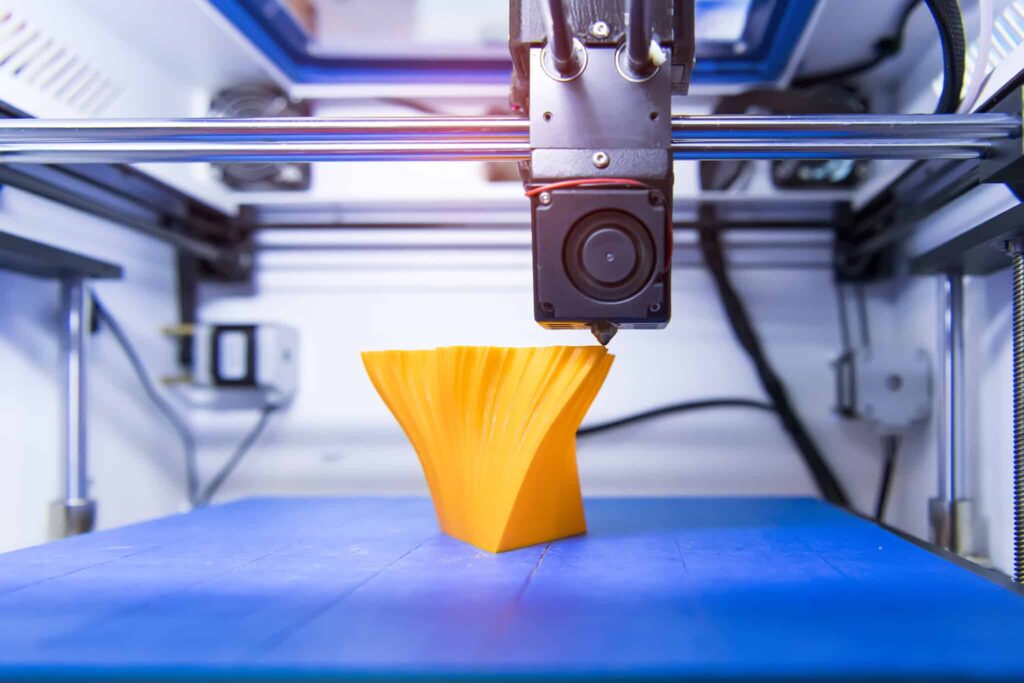

It includes an entrancing excursion through expulsion, cooling, and spooling, each step painstakingly intended to convey the ideal equilibrium of adaptability, strength, and accuracy.

Go along with me on this investigation into the complex universe of 3D printing fiber and find the wonders of present-day fabricating that fuel our computerized manifestations.